Compact on-site hydrogen generator(HYSERVE)

Achievement of compact design at a reduced cost

1) Compact design

2) High-purity hydrogen

3) High efficiency

4) Reasonable price

5) Easy operation

6) Many options

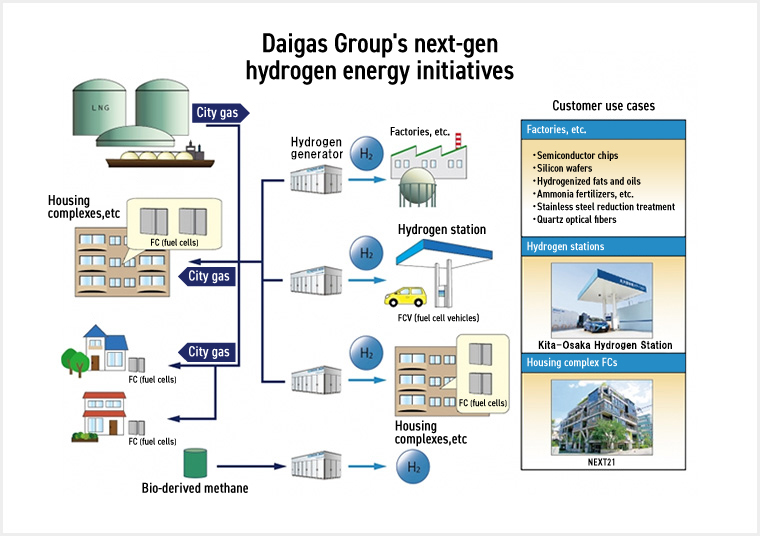

Initiatives

To help creating a next-generation society with hydrogen gas, Daigas Group have been developing equipment and systems for industrial, household and transportation markets based on its technical expertise through city gas business.

Features

Compact design for on-site use

・Pressurized reformer facilitates a compact design, which is free from the High-Pressure Gas Safety Act.

・Compact design by improvement in PSA and off-gas control methods.

・The improved design reduce heat loss and pressure drop.

・Package design of reforming and PSA unit for easy and flexible installation.

High-purity hydrogen

High-purity (99.999%+) on-site hydrogen production using natural gas supplied by city gas pipeline.

High efficiency

・Availability of low and medium pressure natural gas as feedstock, where medium pressure feedstock further allows reduction in compression power.

・Use of PSA off-gases as fuel of the burner which helps reducing the fuel consumption.

Reasonable price

・Reduced on-site construction costs by packaged structure.

Easy operation

・Automatic operation by using single button.

・Automated load switching between 40 - 100% and standby operations as well as user-friendly system.

・Start hydrogen production in 1 hour from hot standby mode.

Optional

・Remote monitoring systems.

・Explosion proof specification (Although standard unit is non-explosion proof, it can be supplied based on customer requirement).

Application

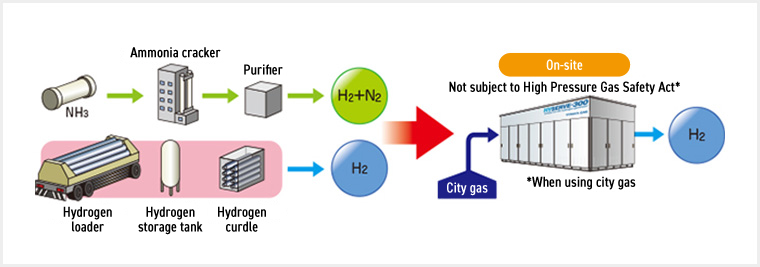

HYSERVE allows hydrogen to be supplied on-site without hydrogen loading truck , H2 cylinder or ammonia cracker. HYSERVE can supply high-purity hydrogen at lower price with stable manner while also consuming minimal space.

Metals

・Powder metallurgy, metal heat treatment (stainless steel bright annealing, galvanized steel sheet reduction treatment, combustion furnace protective gas)

・Magnetic iron powder

・Metal sintering, etc.

Glass and ceramics

・Flat glass manufacturing

・Fused quartz manufacturing

・Fused quartz processing

・Optical fibers

・Ceramic packaging, etc.

Electronics, chemicals, foods, etc.

・Flame processing of electronics

・Semiconductors

・Silicon wafers

・Hydrogenated petroleum resin

・Chemical products

・Manufacture of catalysts

・Oils, fats, etc.

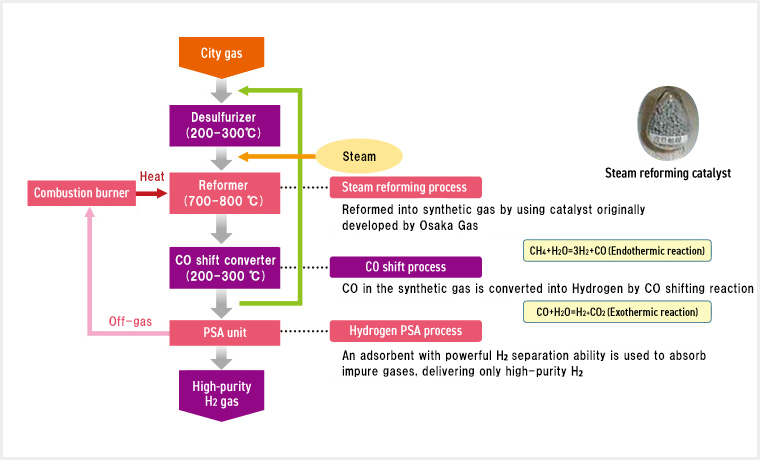

Flow

Operation flow

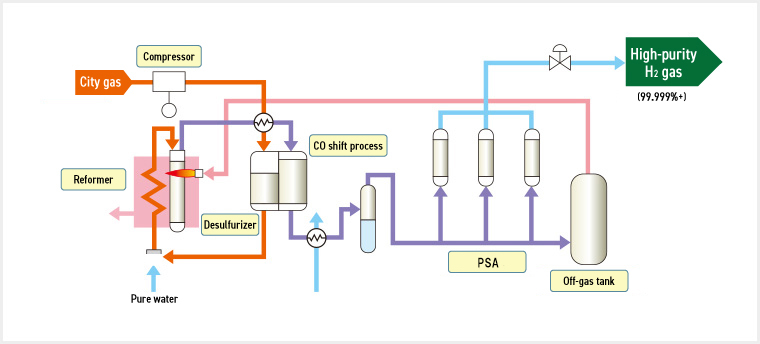

Process flow

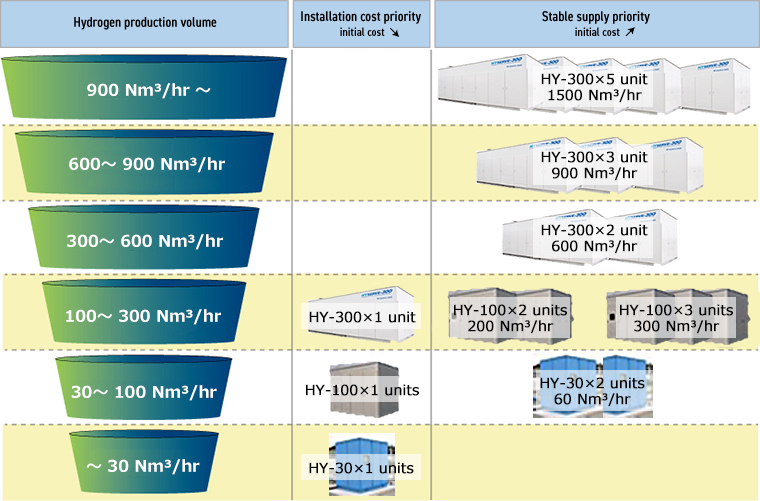

Specifications and models

Specifications

| Models | HYSERVE-30 | HYSERVE-100 | HYSERVE-300 |

| Feedstock | Natural gas, Propane | Natural gas | Natural gas, Propane |

| Hydrogen production capacity | 30Nm2/h | 100Nm2/h | 300Nm2/h |

| Hydrogen purity | 99.999 vol% or higher | ||

| Hydrogen supply pressure | Up to 0.7 MPaG | ||

| Operability | Automated one-touch load adjustment (40-100%), standby operation | ||

| Unit size ※ | Unit package 3,600W×2,000L ×2,950H |

Unit package 5,300W×2,750L ×3,450H |

Unit package 9,700W×3,000L ×3,550H |

| Optional function | Remote monitoring system, etc. | ||

※Unit sizing may be subject to change

Customized to hydrogen volume needs

The development of the 30 Nm2/h, 100 Nm2/h, and 300 Nm2/h HYSERVE models now allows for the support of a wide range of usage scales. Various other needs can be met by combining multiple units via optimum operation control methods.

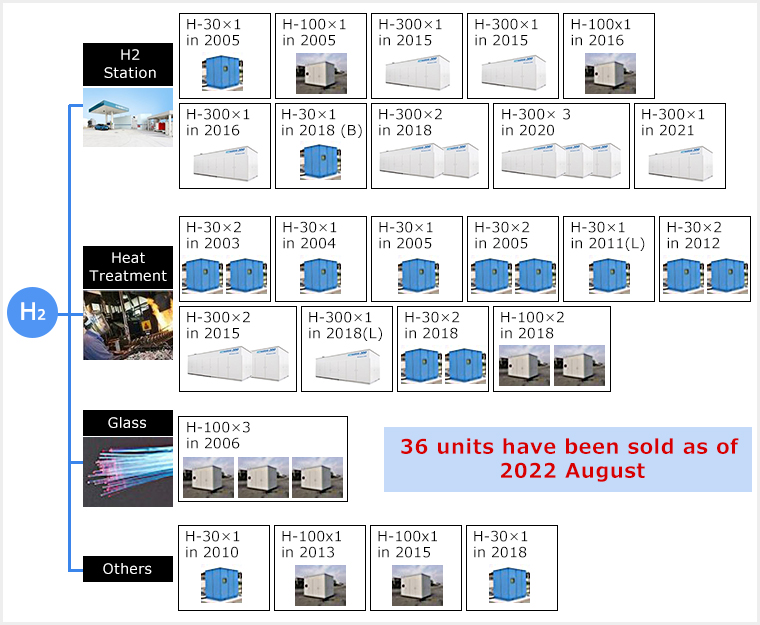

Sales records

Sales records

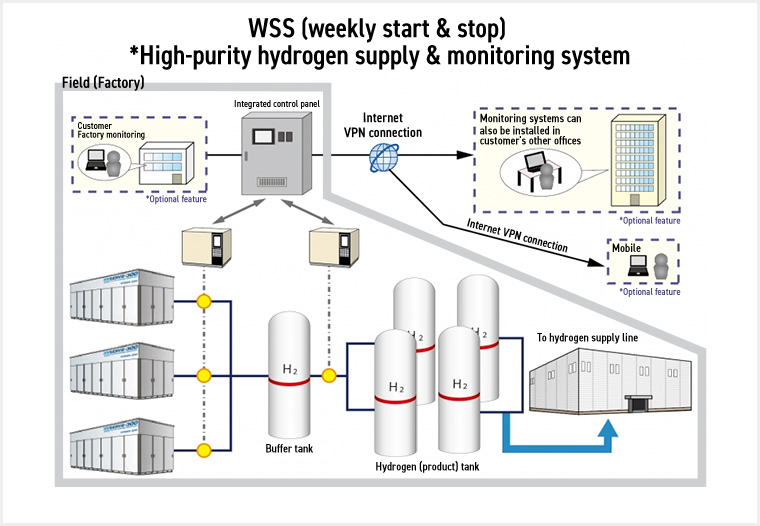

WSS (weekly start & stop)

※High-purity hydrogen supply & monitoring system

We can support designs for demand-sensitive systems that use hydrogen tank pressure to automatically shift between idling and hydrogen production (e.g. in response to lower weekend demand). Systems can also be made to support the remote collection and management of information such as operating status and hydrogen quality.

※We have also provided systems that use continual analysis of hydrogen gas to supply high-purity hydrogen to a production process.