Power Generation Business

Thermal power plants

Thermal power generation: natural gas

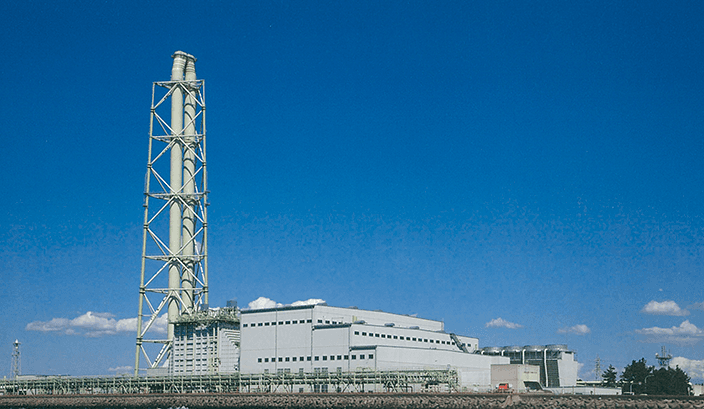

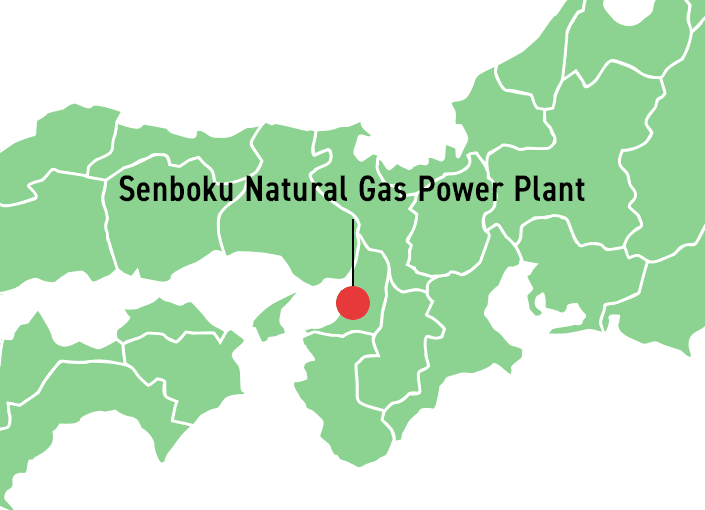

Senboku Natural Gas Power Plant

The Senboku Natural Gas Power Plant, located in one part of the Senboku Terminal, has been operating since FY 2009 with a power generation capacity of 1.10M kW. This facility uses natural gas supplied by the Senboku Terminal to generate electricity using a highly efficient and clean gas turbine combined cycle power generation system.

| Business operator | Senboku Natural Gas Power Generation Co., Ltd. |

| Facility overview | Gas turbine combined cycle power generation |

| Output | 1,109,000kW |

| Address | Sakai-shi and Takaishi-shi, Osaka Prefecture |

| Operations commenced | April 2009 |

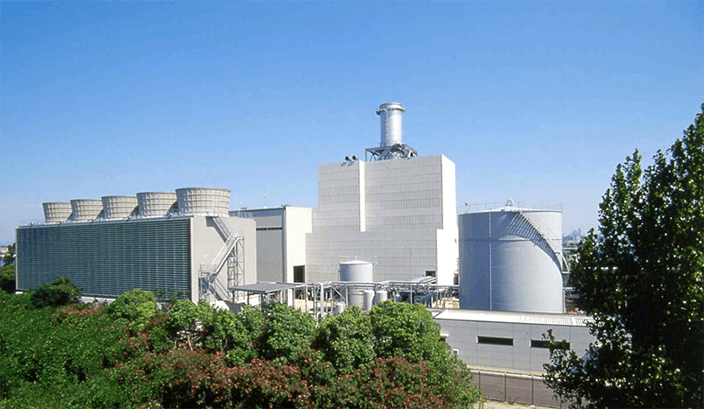

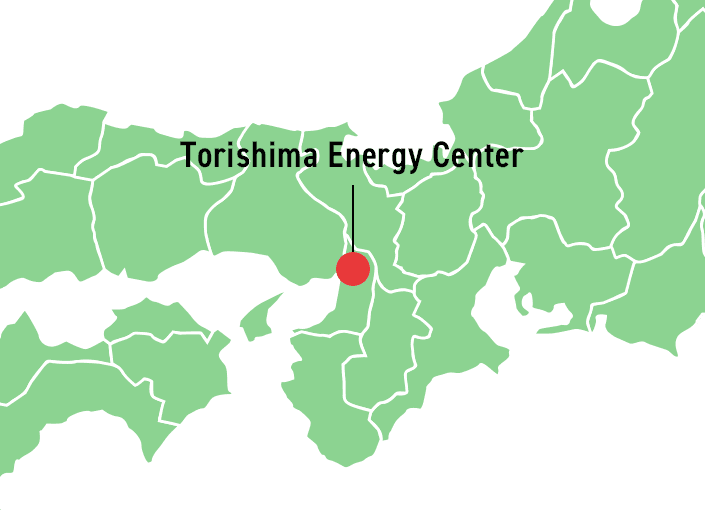

Torishima Energy Center

This site is a gas turbine combined cycle (GTCC) power plant that is the mainstream approach to gas-fired power generation. This project led the Daigas Group's growth in power generation by utilizing a gas turbine combined cycle method to collect exhaust heat generated by gas turbines on the Daigas Group's premises and reutilize this in steam turbines to generate power more efficiently. A daily start-and-stop (DSS) system is used to start and stop operations each day, ensuring this power generation facility is equipped to support the growing demand for electricity during daytime hours. Through a range of initiatives that include use of municipal gas that does not produce sulfur oxide or dust and soot, reductions in nitrogen oxides, sound insulation measures through use of low noise equipment, and prevention of heat drainage discharge through circulatory cooling measures in facilities, we keep our environmental impact to a minimum.

| Business operator | Daigas Gas and Power Solution Co., Ltd. |

| Facility overview | Gas turbine combined cycle power generation |

| Output | 145,000kW |

| Address | Torishima, Konohana-ku, Osaka-shi |

| Operations commenced | April 2002 |

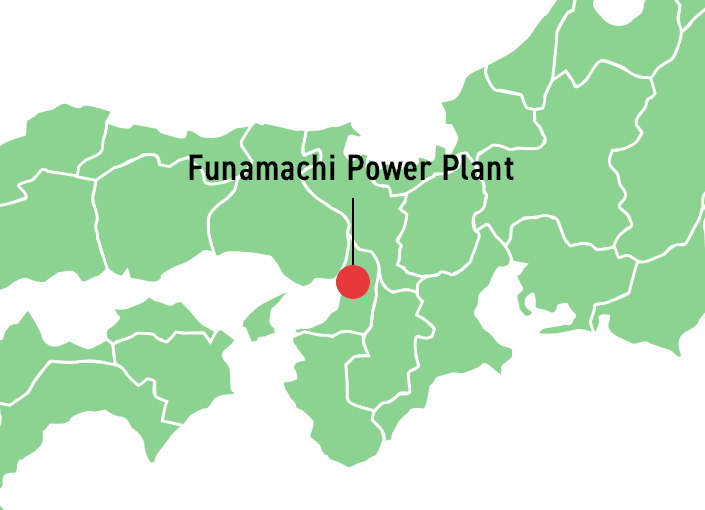

Funamachi Power Plant

This is a gas turbine combined cycle power plant that connects gas and steam turbines into one. In addition, seeking to achieve environmentally-friendly power generation by minimizing our environmental impact, the plant employs a range of initiatives that include use of municipal gas that does not produce sulfur oxide or dust and soot, reductions in nitrogen oxides, sound insulation measures through use of low noise equipment, and prevention of heat drainage discharge through circulatory cooling measures in facilities.

| Business operator | Nakayama Joint Power Generation Co., Ltd. |

| Facility overview | Gas turbine combined cycle power generation |

| Output | 149,000kW |

| Address | Funamachi, Taisho-ku, Osaka-shi |

| Operations commenced | April 1999 |

Thermal power generation [mixed biomass and coal-fired]

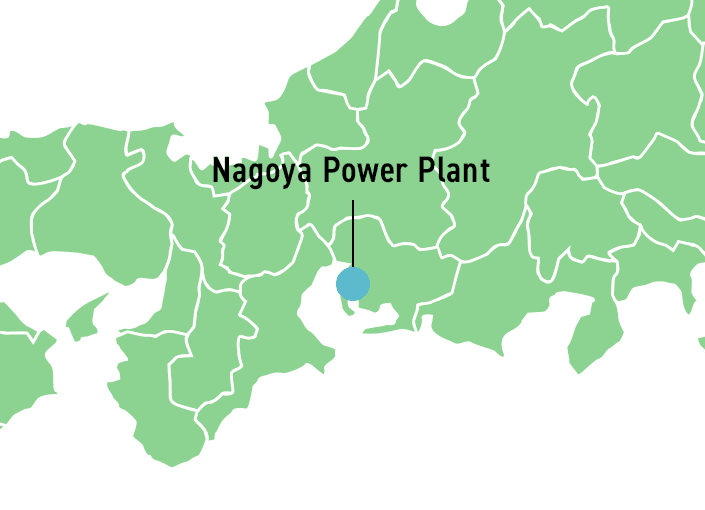

Nagoya Power Plant

This was one of the IPP※ power plants originally launched through a bid by Chubu Electric Power Company. This plant completed its initial 15 year IPP sales contract in March 2015, and is now embarking on a new journey as a commercial plant. The plant had originally used coal power, but was revamped to use a biomass mix. Today, it is actively in use as a mixed biomass coal-fired plant.

※IPP: Independent Power Producer. Following a 1995 amendment to the Electricity Business Act, IPPs solely generating power for the purpose of wholesale were recognized by law.

※Biomass mixed fuel firing

Wood and other biomass fuel is mixed with coal to produce fuel.

Given that the biomass is an organic material, CO2 is generated when it is burned and the energy used. However, since plants absorb CO2 from the atmosphere through photosynthesis as they grow, this makes the biomass a carbon-neutral material, as overall CO2 emissions do not increase as a result.

![Thermal power generation [mixed biomass and coal-fired]](/en/assets/images/service/powergeneration/thermal/pic06.png)

| Business operator | Nakayama Nagoya Joint Power Generation Co., Ltd. |

| Facility overview | Boiler and turbine power generation(Pulverized coal and biomass mixed combustion) |

| Output | 149,000kW |

| Address | Taketoyo-cho, Chita-gun, Aichi Prefecture |

| Operations commenced | April 2000 |

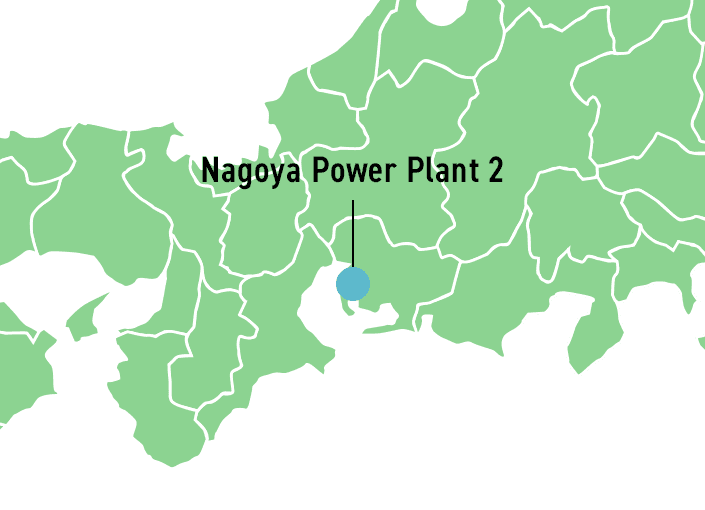

Nagoya Power Plant 2

Located adjacent to the Nagoya Power Plant, this is a new biomass mixed coal-fired plant completed in 2017. The environmentally-friendly fuel mix consists of coal mixed with 30% wood chip biomass to greatly reduce CO2 emissions. Leveraging the expertise gained from the Nagoya Power Plant, which has been online since 2000, this plant pursues efficient operations.

※Biomass mixed fuel firing

Wood and other biomass fuel is mixed with coal to produce fuel.

Given that the biomass is an organic material, CO2 is generated when it is burned and the energy used. However, since plants absorb CO2 from the atmosphere through photosynthesis as they grow, this makes the biomass a carbon-neutral material, as overall CO2 emissions do not increase as a result.

| Business operator | Nakayama Nagoya Joint Power Generation Co., Ltd. |

| Facility overview | Boiler and turbine power generation(Pulverized coal and biomass mixed combustion) |

| Output | 110,000kW |

| Address | Taketoyo-cho, Chita-gun, Aichi Prefecture |

| Operations commenced | September 2017 |