Shuttle lining method

This method uses an epoxy resin lining film on the inner surface of gas pipes to prevent joint and corrosion leakage of gas supply pipes and lighting inner-outer tubing.

Purpose

This method uses an epoxy resin lining film on the inner surface of gas pipes to prevent joint and corrosion leakage of gas supply pipes and lighting inner-outer tubing.

This method is in compliance with the evaluation criteria of the Rehabilitation Repair Method stipulated in the "Guidelines for Countermeasures Against Corrosion of Internal Pipes" and has a confirmed durability of 40 years or more.

Furthermore, technological advances have extended the scope of application. The method now supports pipes with diameters that could not previously be handled.

How it works & benefits

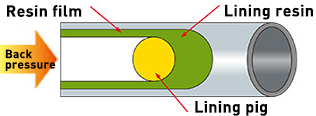

How it works

Lining resin is injected into a pas pipe to produce a uniformly distributed film on the inner surface. Air pressure is then used to push a spherical lining pig through the resin.

Benefits

・Improves airtightness of existing gas pipes, reducing construction costs.

・The method can also be used simultaneously with main branch pipe replacement, improving construction efficiency.

・Lining work can be done by a single individual, with approximately 60-75 minutes required per pipe.

・The compact size of the road tools allows for co-loading with other tools on the same vehicle.

・Can be used on perpendicular pipes within a distance of 8 m.

・Can be used with buried piping of varying diameters (25x32 A, 32x40 A). (Requires diameter-specific pigs)

Scope of application

| Pipe type | Threaded-joint steel pipes |

| Size | 25-50 A (Also support reduced diameter piping) |

Supported extensions

| Pipe diameter | 25A | 32A | 40A | 50A | 25A-32A | 32A-40A | |

| Supported extensions | Summer use | 22m | 22m | 24m | 20m | 22m | 22m |

| Winter use | 16m | 22m | 24m | 20m | 16m | 22m | |

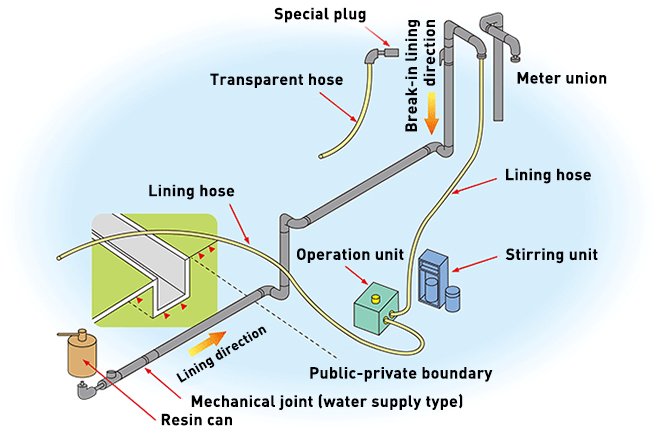

Schematic diagram

Necessary equipment, road tools

| Product number | Product name | Standard (mm) |

| 1 | Operation unit with built-in micro compressor | (W)400×(L)300×(H)290 |

| 2 | Stirring unit, electronic (with timer) | (W)310×(L)345×(H)570 |

| 3 | Injection jig | (H)280×230 |

| 4 | Single lining pig (25 A) | 外径24.0Φ+1.0~-0.5 |

| 5 | Single lining pig(32A) | 32.0Φ+1.0~-0.5 |

| 6 | Single lining pig(40A) | 37.5Φ+1.0~-0.5 |

| 7 | Single lining pig(50A) | 47.5Φ+1.0~-0.5 |

| 8 | Special plug | 25A、32A、40A、50A |

| 9 | Other hosing | - |

Lining agent

| Category | Standard | |

| Type | Epoxy resin (two-liquid mixture, base and hardener) | |

| Curing conditions | Cures at room temperature | |

| Curing time (23℃) | 24+ hours | |

| Viscosity | Base | 200+ P |

| Hardener | 170+ P | |

| Mixture | 150-800 P | |

| Working time | Within 2 hours | |

| Type | Summer type (May-October) ※Usage period may vary by location | |

| Winter type (November-April) ※Usage period may vary by location | ||